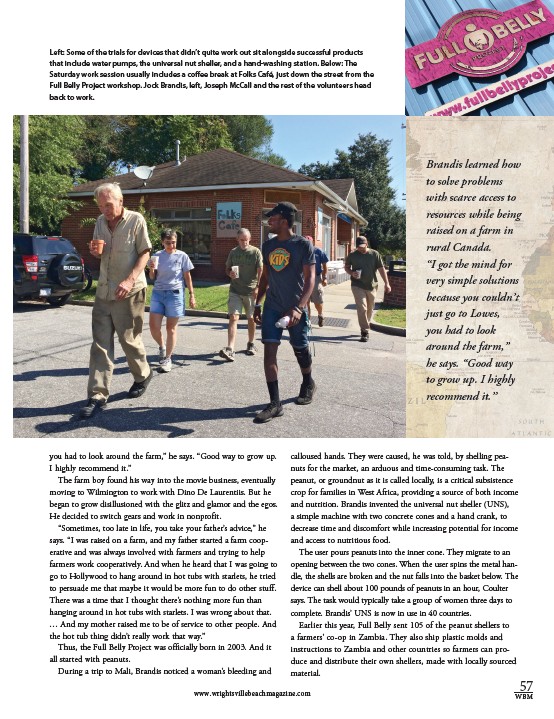

Left: Some of the trials for devices that didn’t quite work out sit alongside successful products

that include water pumps, the universal nut sheller, and a hand-washing station. Below: The

Saturday work session usually includes a coffee break at Folks Café, just down the street from the

Full Belly Project workshop. Jock Brandis, left, Joseph McCall and the rest of the volunteers head

back to work.

Brandis learned how

to solve problems

with scarce access to

resources while being

raised on a farm in

rural Canada.

“I got the mind for

very simple solutions

because you couldn’t

just go to Lowes,

you had to look

around the farm,”

he says. “Good way

to grow up. I highly

recommend it.”

peanut, or groundnut as it is called locally, is a critical subsistence

crop for families in West Africa, providing a source of both income

and nutrition. Brandis invented the universal nut sheller (UNS),

a simple machine with two concrete cones and a hand crank, to

decrease time and discomfort while increasing potential for income

and access to nutritious food.

The user pours peanuts into the inner cone. They migrate to an

opening between the two cones. When the user spins the metal han-dle,

the shells are broken and the nut falls into the basket below. The

57

you had to look around the farm,” he says. “Good way to grow up.

I highly recommend it.”

The farm boy found his way into the movie business, eventually

moving to Wilmington to work with Dino De Laurentiis. But he

began to grow disillusioned with the glitz and glamor and the egos.

He decided to switch gears and work in nonprofit.

“Sometimes, too late in life, you take your father’s advice,” he

says. “I was raised on a farm, and my father started a farm coop-erative

and was always involved with farmers and trying to help

farmers work cooperatively. And when he heard that I was going to

go to Hollywood to hang around in hot tubs with starlets, he tried

to persuade me that maybe it would be more fun to do other stuff.

There was a time that I thought there’s nothing more fun than

hanging around in hot tubs with starlets. I was wrong about that.

… And my mother raised me to be of service to other people. And

the hot tub thing didn’t really work that way.”

Thus, the Full Belly Project was officially born in 2003. And it

all started with peanuts.

During a trip to Mali, Brandis noticed a woman’s bleeding and

calloused hands. They were caused, he was told, by shelling pea-nuts

for the market, an arduous and time-consuming task. The

device can shell about 100 pounds of peanuts in an hour, Coulter

says. The task would typically take a group of women three days to

complete. Brandis’ UNS is now in use in 40 countries.

Earlier this year, Full Belly sent 105 of the peanut shellers to

a farmers’ co-op in Zambia. They also ship plastic molds and

instructions to Zambia and other countries so farmers can pro-duce

and distribute their own shellers, made with locally sourced

material.

www.wrightsvillebeachmagazine.com WBM