trending

Prosthetic Device Athlete

Marc Dunshee, a local runner and amputee who regularly

competes in marathons, utilizes Trivisonno’s prostheses dur-ing

everyday activities as well as trainings and competitions.

This includes a prosthetic blade, which Dunshee uses when

running on slippery surfaces. With more than 2,000 miles

logged on his prostheses, Dunshee’s weekly training regimen

includes several five-plus mile runs combined with biking to

and running on Wrightsville Beach.

“Dunshee is by far the most active amputee in our area

and has used this device more than any patient I’ve ever

worked with previously in private practice,” Trivisonno says.

In addition to mitigating learning curves, Trivisonno aims

to save costs for both himself and his clients, especially pro-duction

and healthcare reimbursement costs. He expects the

demand for prostheses to increase in coming years, mainly

due to the rising prevalence of diabetes, vascular issues

and cancer. With this, Trivisonno has a growing demand

for hemp fabric. Currently, he imports hemp textiles from

China, where material costs are cheap but shipping costs

remain expensive due to tariffs on imported yarn. Ideally, he

would prefer to use locally grown hemp.

“We have super-strong material all around us,” he says.

And with the passage of the state pilot program combined

with the increasingly realized benefits of growing hemp, it

seems natural to produce it on local land.

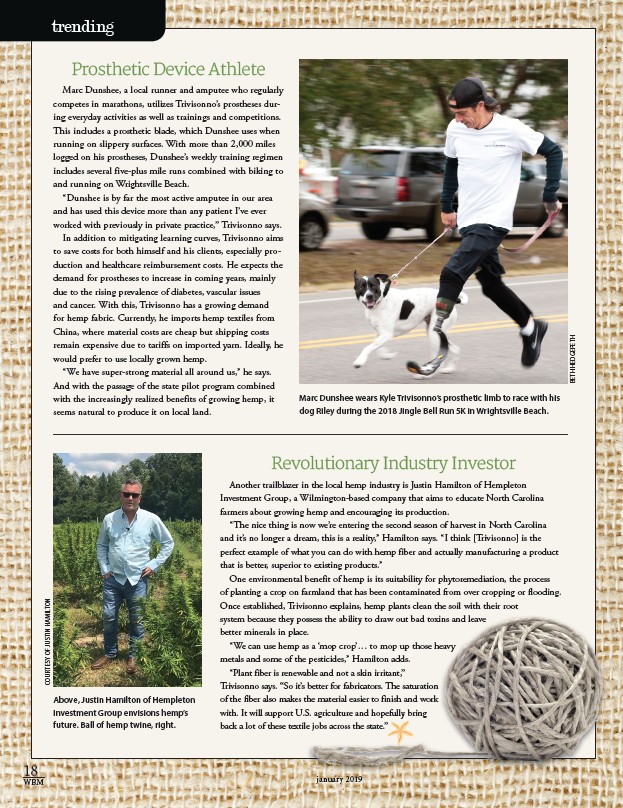

Marc Dunshee wears Kyle Trivisonno’s prosthetic limb to race with his

dog Riley during the 2018 Jingle Bell Run 5K in Wrightsville Beach.

Revolutionary Industry Investor

Another trailblazer in the local hemp industry is Justin Hamilton of Hempleton

Investment Group, a Wilmington-based company that aims to educate North Carolina

farmers about growing hemp and encouraging its production.

“The nice thing is now we’re entering the second season of harvest in North Carolina

and it’s no longer a dream, this is a reality,” Hamilton says. “I think Trivisonno is the

perfect example of what you can do with hemp fiber and actually manufacturing a product

that is better, superior to existing products.”

One environmental benefit of hemp is its suitability for phytoremediation, the process

of planting a crop on farmland that has been contaminated from over cropping or flooding.

Once established, Trivisonno explains, hemp plants clean the soil with their root

system because they possess the ability to draw out bad toxins and leave

better minerals in place.

“We can use hemp as a ‘mop crop’… to mop up those heavy

metals and some of the pesticides,” Hamilton adds.

“Plant fiber is renewable and not a skin irritant,”

Trivisonno says. “So it’s better for fabricators. The saturation

of the fiber also makes the material easier to finish and work

with. It will support U.S. agriculture and hopefully bring

back a lot of these textile jobs across the state.”

Above, Justin Hamilton of Hempleton

Investment Group envisions hemp’s

future. Ball of hemp twine, right.

COURTESY OF JUSTIN HAMILTON

18

WBM january 2019

BETH HEDGEPETH