TUART KENT, the featured presenter at a monthly gathering of the

Wilmington Area Woodturners Association (WAWA), fearlessly rose to the

challenge of turning a log, scarred with a deep hole, into a set of bowls.

A bowl is often the first piece for a beginning woodturner, but there is a

learning curve that starts with some basic techniques. Kent is no novice; hav-ing

worked with wood for more than 25 years, he makes the craft look easy.

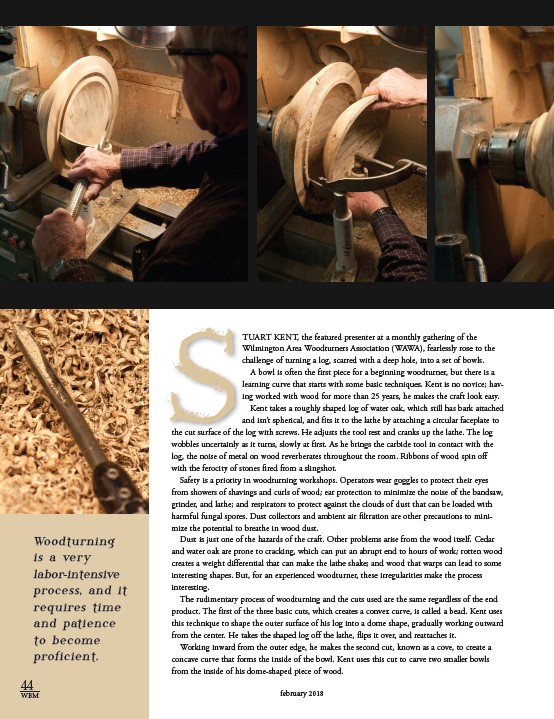

Kent takes a roughly shaped log of water oak, which still has bark attached

and isn’t spherical, and fits it to the lathe by attaching a circular faceplate to

the cut surface of the log with screws. He adjusts the tool rest and cranks up the lathe. The log

wobbles uncertainly as it turns, slowly at first. As he brings the carbide tool in contact with the

log, the noise of metal on wood reverberates throughout the room. Ribbons of wood spin off

with the ferocity of stones fired from a slingshot.

Safety is a priority in woodturning workshops. Operators wear goggles to protect their eyes

from showers of shavings and curls of wood; ear protection to minimize the noise of the bandsaw,

grinder, and lathe; and respirators to protect against the clouds of dust that can be loaded with

harmful fungal spores. Dust collectors and ambient air filtration are other precautions to mini-mize

the potential to breathe in wood dust.

Dust is just one of the hazards of the craft. Other problems arise from the wood itself. Cedar

and water oak are prone to cracking, which can put an abrupt end to hours of work; rotten wood

creates a weight differential that can make the lathe shake; and wood that warps can lead to some

interesting shapes. But, for an experienced woodturner, these irregularities make the process

interesting.

The rudimentary process of woodturning and the cuts used are the same regardless of the end

product. The first of the three basic cuts, which creates a convex curve, is called a bead. Kent uses

this technique to shape the outer surface of his log into a dome shape, gradually working outward

from the center. He takes the shaped log off the lathe, flips it over, and reattaches it.

Working inward from the outer edge, he makes the second cut, known as a cove, to create a

concave curve that forms the inside of the bowl. Kent uses this cut to carve two smaller bowls

from the inside of his dome-shaped piece of wood.

february 2018

Woodturning

is a very

labor-intensive

process, and it

requires time

and patience

to become

proficient.

44

WBM