13

www.wrightsvillebeachmagazine.com WBM

Burchetta, the production

glass blowing facility

that relocated from West

Chester, New York, to

Wilmington, North Carolina, three years

ago, is an inferno of furnaces and ovens

on Myrtle Grove Sound Road.

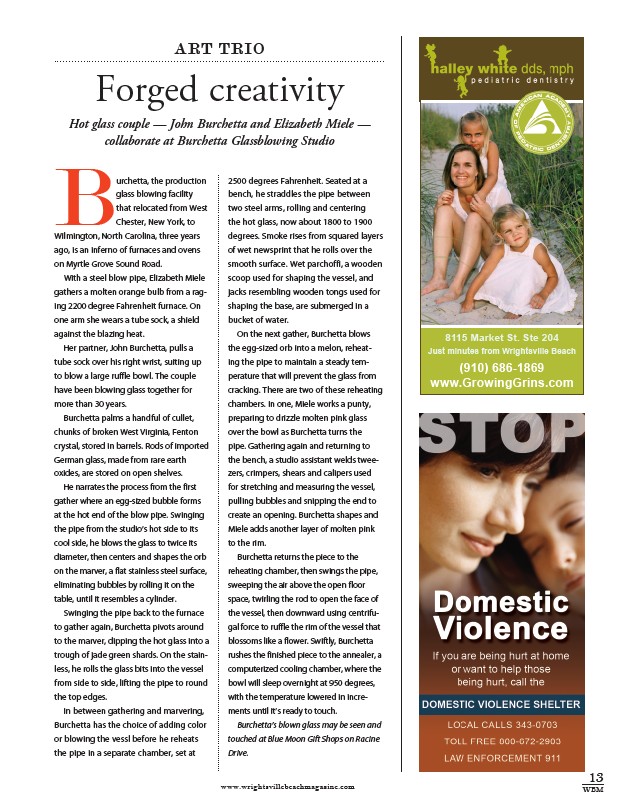

With a steel blow pipe, Elizabeth Miele

gathers a molten orange bulb from a raging

2200 degree Fahrenheit furnace. On

one arm she wears a tube sock, a shield

against the blazing heat.

Her partner, John Burchetta, pulls a

tube sock over his right wrist, suiting up

to blow a large ruffle bowl. The couple

have been blowing glass together for

more than 30 years.

Burchetta palms a handful of cullet,

chunks of broken West Virginia, Fenton

crystal, stored in barrels. Rods of imported

German glass, made from rare earth

oxides, are stored on open shelves.

He narrates the process from the first

gather where an egg-sized bubble forms

at the hot end of the blow pipe. Swinging

the pipe from the studio’s hot side to its

cool side, he blows the glass to twice its

diameter, then centers and shapes the orb

on the marver, a flat stainless steel surface,

eliminating bubbles by rolling it on the

table, until it resembles a cylinder.

Swinging the pipe back to the furnace

to gather again, Burchetta pivots around

to the marver, dipping the hot glass into a

trough of jade green shards. On the stainless,

he rolls the glass bits into the vessel

from side to side, lifting the pipe to round

the top edges.

In between gathering and marvering,

Burchetta has the choice of adding color

or blowing the vessl before he reheats

the pipe in a separate chamber, set at

2500 degrees Fahrenheit. Seated at a

bench, he straddles the pipe between

two steel arms, rolling and centering

the hot glass, now about 1800 to 1900

degrees. Smoke rises from squared layers

of wet newsprint that he rolls over the

smooth surface. Wet parchoffi, a wooden

scoop used for shaping the vessel, and

jacks resembling wooden tongs used for

shaping the base, are submerged in a

bucket of water.

On the next gather, Burchetta blows

the egg-sized orb into a melon, reheating

the pipe to maintain a steady temperature

that will prevent the glass from

cracking. There are two of these reheating

chambers. In one, Miele works a punty,

preparing to drizzle molten pink glass

over the bowl as Burchetta turns the

pipe. Gathering again and returning to

the bench, a studio assistant welds tweezers,

crimpers, shears and calipers used

for stretching and measuring the vessel,

pulling bubbles and snipping the end to

create an opening. Burchetta shapes and

Miele adds another layer of molten pink

to the rim.

Burchetta returns the piece to the

reheating chamber, then swings the pipe,

sweeping the air above the open floor

space, twirling the rod to open the face of

the vessel, then downward using centrifugal

force to ruffle the rim of the vessel that

blossoms like a flower. Swiftly, Burchetta

rushes the finished piece to the annealer, a

computerized cooling chamber, where the

bowl will sleep overnight at 950 degrees,

with the temperature lowered in increments

until it’s ready to touch.

Burchetta’s blown glass may be seen and

touched at Blue Moon Gift Shops on Racine

Drive.

8115 Market St. Ste 204

Just minutes from Wrightsville Beach

(910) 686-1869

www.GrowingGrins.com

Art Trio

Forged creativity

Hot glass couple — John Burchetta and Elizabeth Miele —

collaborate at Burchetta Glassblowing Studio