www.wrightsvillebeachmagazine.com 47

WBM

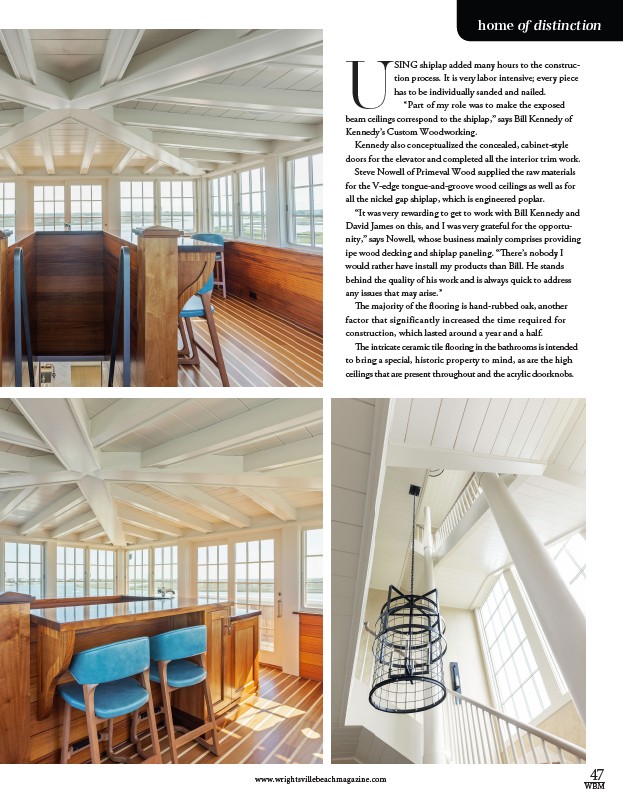

USING shiplap added many hours to the construc-tion

process. It is very labor intensive; every piece

has to be individually sanded and nailed.

“Part of my role was to make the exposed

beam ceilings correspond to the shiplap,” says Bill Kennedy of

Kennedy’s Custom Woodworking.

Kennedy also conceptualized the concealed, cabinet-style

doors for the elevator and completed all the interior trim work.

Steve Nowell of Primeval Wood supplied the raw materials

for the V-edge tongue-and-groove wood ceilings as well as for

all the nickel gap shiplap, which is engineered poplar.

“It was very rewarding to get to work with Bill Kennedy and

David James on this, and I was very grateful for the opportu-nity,”

says Nowell, whose business mainly comprises providing

ipe wood decking and shiplap paneling. “There’s nobody I

would rather have install my products than Bill. He stands

behind the quality of his work and is always quick to address

any issues that may arise.”

The majority of the flooring is hand-rubbed oak, another

factor that significantly increased the time required for

construction, which lasted around a year and a half.

The intricate ceramic tile flooring in the bathrooms is intended

to bring a special, historic property to mind, as are the high

ceilings that are present throughout and the acrylic doorknobs.

home of distinction