savor

Artisan cheesemakers let the milk dictate how the cheese will be

made and aged, which invariably leads to variations in taste across

the seasons.”

Nathan was a CPA and portfolio manager with an investment

advisory firm before getting into the cheesemaking business.

“I started making cheese in my spare time as a serious hobby

with the expectation that it might become a second career once I

retired from my day job,” he says.

He started with a few weekend cheesemaking workshops,

attended an intensive program at the Sterling College Artisan

Cheese Institute in Vermont, and in 2017 completed an advanced

program at Westminster Artisan Cheesemaking taught by cheese-maker

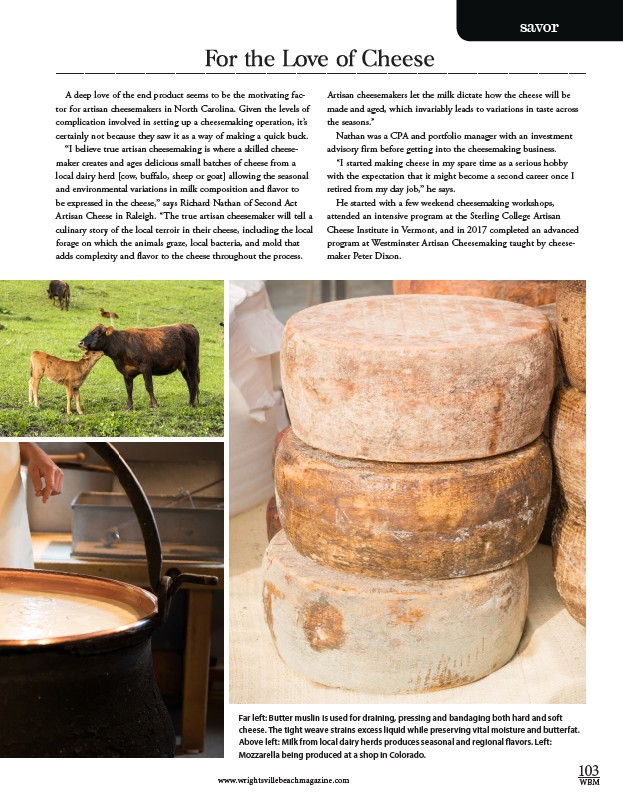

Far left: Butter muslin is used for draining, pressing and bandaging both hard and soft

cheese. The tight weave strains excess liquid while preserving vital moisture and butterfat.

Above left: Milk from local dairy herds produces seasonal and regional flavors. Left:

Mozzarella being produced at a shop in Colorado.

103

A deep love of the end product seems to be the motivating fac-tor

for artisan cheesemakers in North Carolina. Given the levels of

complication involved in setting up a cheesemaking operation, it’s

certainly not because they saw it as a way of making a quick buck.

“I believe true artisan cheesemaking is where a skilled cheese-maker

creates and ages delicious small batches of cheese from a

local dairy herd cow, buffalo, sheep or goat allowing the seasonal

and environmental variations in milk composition and flavor to

be expressed in the cheese,” says Richard Nathan of Second Act

Artisan Cheese in Raleigh. “The true artisan cheesemaker will tell a

culinary story of the local terroir in their cheese, including the local

forage on which the animals graze, local bacteria, and mold that

adds complexity and flavor to the cheese throughout the process.

Peter Dixon.

www.wrightsvillebeachmagazine.com WBM