THE FISHERY

In 1960, the commercial menhaden industry was the largest of all fisheries in

the United States with a recorded catch of over 1 million tons. The majority of

the catch came from East Coast ports such as Southport.

Menhaden, known locally as pogies, live in estuaries and warm coastal waters.

As the waters cool during the fall, the species migrates to the ocean and moves

along the coast in mammoth schools pulsing with millions of fish.

Menhaden have been sought after since colonial times as raw material for

fertilizer, oils and supplements. Critical to the Atlantic Ocean food chain, the

small fish are prey for numerous natural predators including channel bass,

striped bass, tuna, trout, dolphins, eagles and ospreys.

The Southport menhaden fishery was active most of the year, but the autumn

months were spectacular.

BOATS AND GEAR

The Standard Products Fleet, which owned the Anderson, used commercial

purse seines to catch menhaden. A mainstay of the menhaden fleet, the purse

seine in 1960 was made of cotton mesh about 1,000 feet long with a depth of

around 50 feet.

The typical Standard Products Company ship was a vessel over 100 feet

referred to as the mother ship that carried two smaller purse boats of some

30 feet each. The usual fishing crew was 24 able-bodied men with 10 men each

on the purse boats and the remainder on the mother boat.

When menhaden were spotted from the air, the boat, led by the pilot’s VHF radio, would rally to intercept the school. The spotter

would direct the net deployment, known as the set, depending on the wind, current, and size of the school.

The purse boats, each laden with one half of the net’s length, deployed from the stern of the mother boat. They would move to oppo-site

sides of the school to form an open U shape around the perimeter.

The U was cinched tight by the crewmen, capturing the fish in the “purse.” It took about 30 minutes until the net was closed. Origi-nally

the nets were retrieved by hand with backbreaking work from strong seamen, but later mechanical winches performed the task.

The fish were loaded into the mother boat which, when filled, would rush back to the plant in Southport and offload the catch at the

Standard Products factory. In 1960, ships were not equipped with refrigeration and stored the catch in uninsulated fish holds. Boats

had to operate close to the landing point to prevent spoilage. Most sets occurred within three miles of shore, with the majority being

just off the coast of Brunswick County.

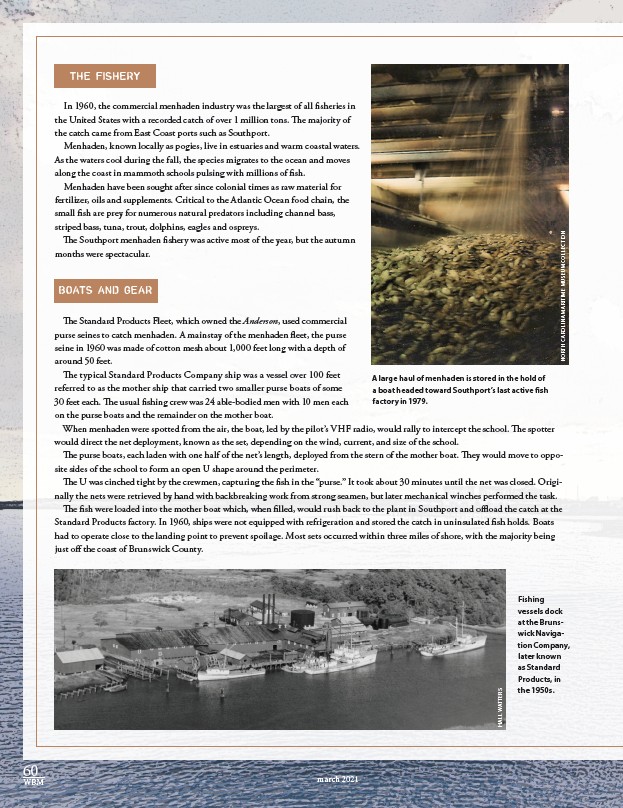

Fishing

vessels dock

at the Bruns-wick

Naviga-tion

Company,

later known

as Standard

Products, in

the 1950s.

60

WBM march 2021

A large haul of menhaden is stored in the hold of

a boat headed toward Southport’s last active fish

factory in 1979.

HALL WATTERS

NORTH CAROLINA MARITIME MUSEUM COLLECTION